关于我们

关于我们

青岛瑞鑫泰益祥科技有限公司青岛瑞鑫泰益祥科技有限公司青岛瑞鑫泰益祥科技有限公司坐落于青岛市高新技术产业区,公司成立于2003年,是一家集设计、开发、生产和营销为一体的专业化、现代化机械加工企业。公司始终秉承“以质量求生存,以信誉求发展,以服务为导向,以客户为中心”的核心价值观和“敬人、诚信、敬业、创新”的企业宗旨,不断开拓创新。 |

|

|

质量管理

质量管理

-

质量团队

瑞鑫泰认为质量不是少数人的责任;而是集体的责任。尽管我们只致力于多个人参与质量保证/质量保证体系的具体活动,但我们相信能够在瑞鑫泰授权我们所有的员工,以达到我们的质量标准。

-

质量流程

我们的质量管理流程为我们的客户提供了一个安全的水平,他们的项目在每个操作中都进行了彻底的审查和验证,实现了零件,从RFQ开始,在收到零件后,全面的项目跟踪。

-

质量控制设备

我们拥有最新的质量控制设备,包括我们的CMM(数控和手动),SmartScope视觉系统和Virtek激光扫描功能。我们的所有测量和测试设备都按照ISO标准进行校准,以证明合规性。

-

质量方针

瑞鑫泰的每个人。致力于及时提供符合客户要求的优质产品和增值服务。通过持续改进,我们将满足不断增长的期望。

-

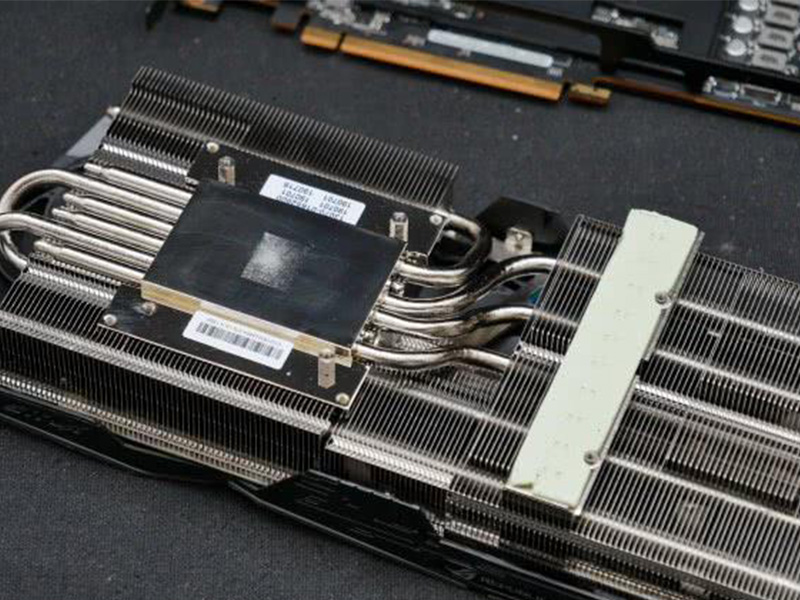

传热散热

RXTAI 多年的经验、对卓越品质的奉献和对客户服务的不懈承诺使我们成为传热行业的主要供应商。

-

电子电器

商业和住宅餐饮服务设备和家电制造商向青岛睿泰有限公司寻求帮助。帮助他们实现生产目标并降低每个零件的成本。

-

电信通讯

QINGDAO RXTAI CO.,LTD 通过准时生产精密、复杂的金属零部件,服务于快速发展的计算机、电信和电子市场。

-

航空航天

RXTAI 自豪地为其军事、国防和航空航天客户提供精密金属零件和准时交货。RXTAI 在为武装、定时和引信延迟行业制造工具和供应生产零件方面拥有丰富的经验。

-

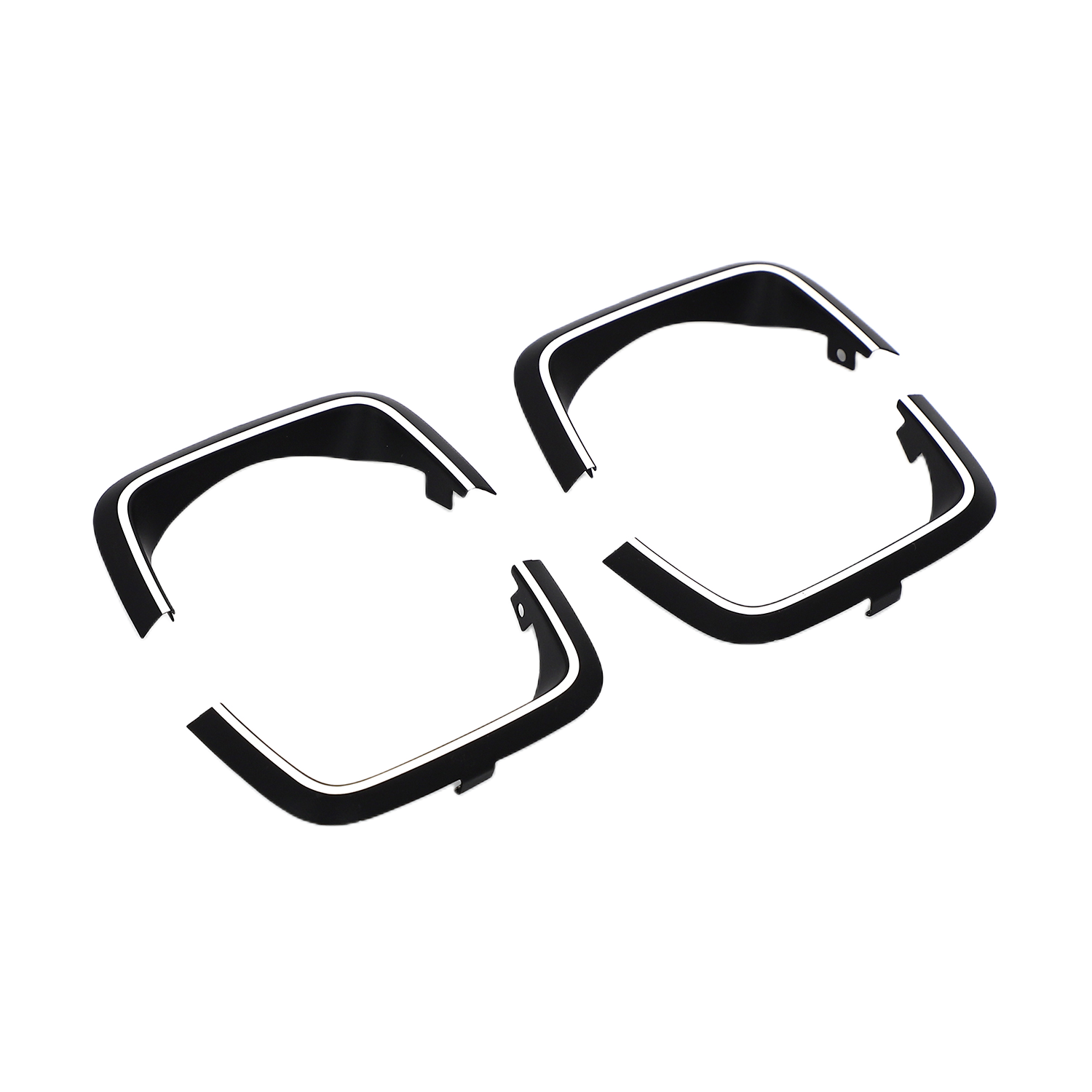

汽车配件

RXTAI 与世界各地的汽车供应商合作,生产需要多种制造工艺的零件,从工具和模具制造到金属制造和冲压。

-

医疗器材

RXTAI 为众多医疗保健设备制造商提供服务,通过生产精确加工的零件、金属制品和组件来满足他们严格的质量要求。

tel:+86133 6126 8081

tel:+86133 6126 8081  Email:wangxiangen@qdrxt.net

Email:wangxiangen@qdrxt.net